Diesel Generator Operation Manual Control System Part 1-1

Control System

1.1 Control System Description

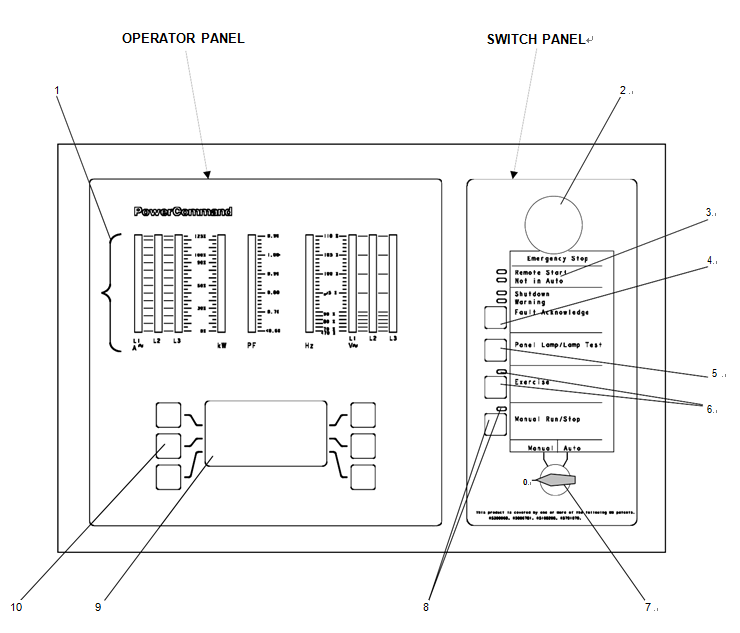

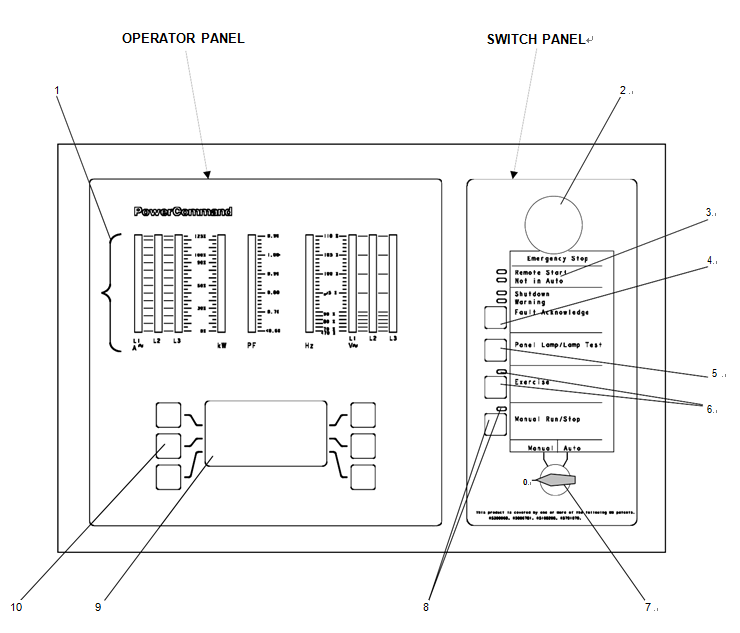

The main control panel consists of two panels, the Operator Panel and the Switch Panel. These and their associated equipment are located in the Control Housing, which is mounted at the rear of the generator set.

Dependent on site requirements the Operator Panel may be mounted in the control panel assembly (full-featured) as shown in Figure 1-1, or it may be contained in a separate enclosure and mounted remotely of the control panel assembly. In this latter case, the panel may be situated up to 1.2km (4,000ft) away from the generator set.

Note: The function of several buttons on the Operator Panel will vary dependent on the location of the Operator Panel (remote or local of the ControlPanel assembly).

If the function differs, it is noted as either Remote or Local Operator Panel in the description.

The control system is a micro-processor based control unit for monitoring and protecting the generator set and can provide automatic paralleling. All indicators, control switches/buttons and the digital display are on the face of the control panel as illustrated in Figure 1-1.

The control system provides fuel control and engine speed governing, main alternator voltage output regulation, and complete generator set control and monitoring. The control also monitors the health of the engine, alternator and auxiliary systems continuously, via an array of sensors and senders located on the generator set, and will affect an Automatic Shutdown if a serious fault occurs.

There are two fault level signals generated by the control system as follows:

1.Warning: signals an imminent or non-fatal fault for the engine. The control provides an indication only for this condition.

2.Shutdown: signals a potentially fatal fault for the engine. The control will automatically take the engine off-load and shut it down immediately, without a cooling down run.

The control system operates on 24V DC battery power. The auxiliary equipment operates on LV AC power. The history data is stored in non-volatile memory and will not be deleted due to loss of battery power.

In addition to the many control and annunciation functions, the PCC 3201 can be easily upgraded to communicate over a PowerCommand™ Network, or to work as part of a paralleling system.

1.1.1 Control Panel Power ON/OFF Modes

The power on/off modes of the control panel and operating software are Power On, Screen Saver and Sleep/Awake.

Power On Mode

In this mode, power is continuously supplied to the control panel. The control’s operating software and control panel LEDs/graphical display will remain active until the Screen Saver mode is activated.

Screen Saver Mode

Power to the graphical display will be removed after ten minutes (generator set not running or running). The ten minute timer resets and begins after each control panel action (any button or switch selection) or signal received by the operating software. The bottom LEDs of the Analogue AC Metering Panel (bar graphs) may remain on during Screen Saver mode, indicating that the operating software is active (Awake mode).

When a Warning signal is sensed by the control, (for example, Low Coolant Temp), a warning message will be displayed. The control will remain active until the Fault Acknowledge button is pressed to clear the warning message and start the ten minute timer.

Sleep/Awake Mode

In the Sleep mode, the control’s operating software is inactive and the LEDs and the graphical display on the control panel are all off. Sleep mode is a feature that is used to reduce battery power consumption when the control is in the Auto mode and is not being used.

When all conditions are met (i.e., no unacknowledged faults, Screen Saver Mode is active, and Off/Manual/Auto switch is in the Auto position) the Sleep mode will be activated.

The operating software is initialised and the control panel LEDs and graphical display are turned on in response to one of the following:

•Moving/pressing any control panel switch/button

•A remote start input signal (generator set in Auto mode)

•Customer fault 2 or 3 only (Shutdown or Warning indicator is on)

To activate the control and view the menu display without starting the generator set, press any button on the control panel.

The InPower service tool is required to enable or disable the Sleep mode. When shipped from the factory, the Sleep mode is disabled. When disabled, the operating software will always remain active (Awake mode) when the control is in Auto mode.

Note: The InPower service tool is required in order to select the desired mode.

Contact your authorised distributor for assistance.

1.1.2Control Panel - Front Panel

Figure 1-1Control Panel Assembly (Full Featured)

1.Analogue AC metering panel 7.Off/Manual/Auto switch (mode switch)

2.Emergency stop push switch (This is a Key Switch)

3.Status indicators 8.Manual Run/Stop button & indicator

4.Fault acknowledge button 9.Graphical display

5.Panel lamp/lamp test button 10.Display menu selection buttons (1 of 6)

6.Exercise button & indicator

1.1.3Control Panel - Operator Panel

The operator panel contains the following components:

Analogue AC Metering Panel:

This panel simultaneously displays 3–phase line-to-line AC volts and current, kW, power factor and frequency.

The meter panel is composed of a series of LEDs that are configured in bar graphs for each function. The LEDs are colour coded, with green indicating normal range values, amber for Warning levels and red for Shutdown conditions.

Scales for each function are in % of nominal values. Resolution is 1% for values close to nominal, and increases for values further from nominal.

Graphical Display:

The graphical display is capable of displaying up to nine lines of data with approximately 27 characters per line. The display is used to view the menus of the menu–driven operating system. (Refer to the menu trees later in this section). The display is also used to show Warning and Shutdown messages/error codes, modes of operation (Figure 1-2) and system actions, such as Warning, De-rate, Shutdown, etc.

Display Menu Selection Buttons:

Six momentary buttons—three on each side of the graphical display window—are used to navigate through the system control menus and to adjust generator set parameters. The button is active when the message adjacent to the button is highlighted (displayed in inverse video).