Hiersun Power Supply Marine Engine Propulsion System To Shipyard Client

Propulsion System Stem Arrangement

For marine propulsion system with engine accessories, control system, steering system, stem arrangement and ventilation blowers

complete for Light Aluminum Craft 2 Sets for each craft and thus 4 Sets are needed for 2 Crafts, The tenderer should consider the following:

1) 2 years warranty While storage.

2) Corrosion inhibition of the engine and propulsion system.

3) Warranty for one year from the date of commissioning of the vessel.

4) Technical .training of buyer's technicians at manufacturer's factory for major overhauling of the engine and system, The tenderer should supply

(B) Main Engine: all under mentioned scope of supply in one package, deal. Scope

of supply is to include all the items even if not mention in the specification so as to tender the whole system complete arid ready for installation.

a) Indirect cooling system

b) Heat exchanger and expansion tanks.

c) Fresh water pump.

d) Fresh water pump for emergency cooling.

e) Raw water pump.

f) Raw water pump for emergency cooling.

g) Flexible hoses with clips,

h) Main sea chest .valves and piping system, for simultaneous use of both main engines,

i) Sea water strainers

j) Corrosion prevention arrangement.

k) Lubricating system

l) Forced feed lubrication of engine and piston cooling by means of engine, driven lubrication oil pump.

m) Oil pan on engine.

n) Lub. oil cooler on engine ,

o) Engine mounted lub. oil duplex filter (change-over type), Pre lub. oil hand pump.

p) Lub. oil centrifuge in auxiliary circuit.

q) Necessary filters with spare elements.

r) Fuel System .

The complete system for safe working of the engines-

(aa) Engine mounted fuelduplex filter, change-over type.

(bb) Piping and valves for Fuel supply lines, Necessary filters with spare elements Speed and load control

(4) Hydraulic speed governor on engine suitable for variable speed operation

(bb) Fuel rack position device, rack positioning manual shut

down devices

intake Air System

(aa Intake air manifold on engine.

(bb) Charge air cooler on engine

E-xhaust System

E-xhaust gas manifold on engine, uncooled but insulated,.

Exhaust gas turbocharger on engine.

Water cool exhaust with water injection ring and connecting flanges for installation on aluminum hull for side exhaust. Exhaust pipes, pipes joint, sufficient. quantity of insulation material for insulation for the exhaust pipe

(1)non-reversible Marine Engine, 4 stroke, water cooled Turbocharged,

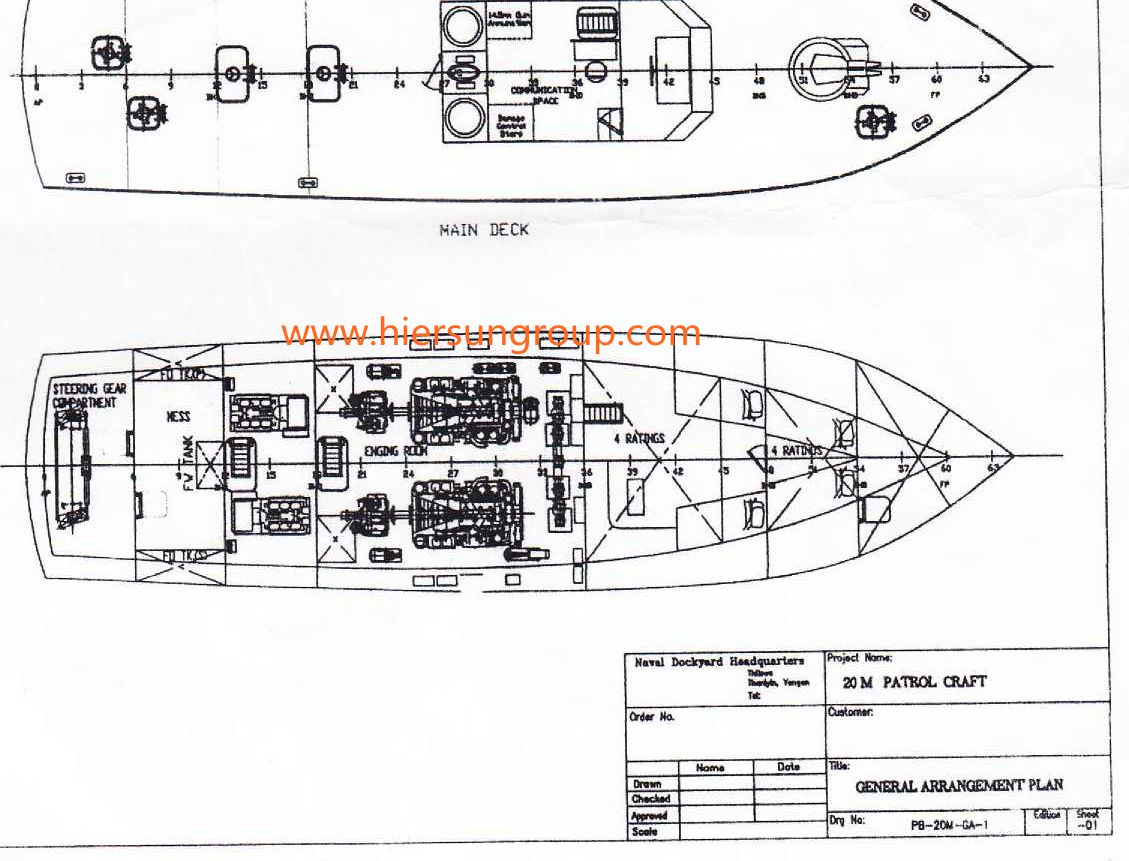

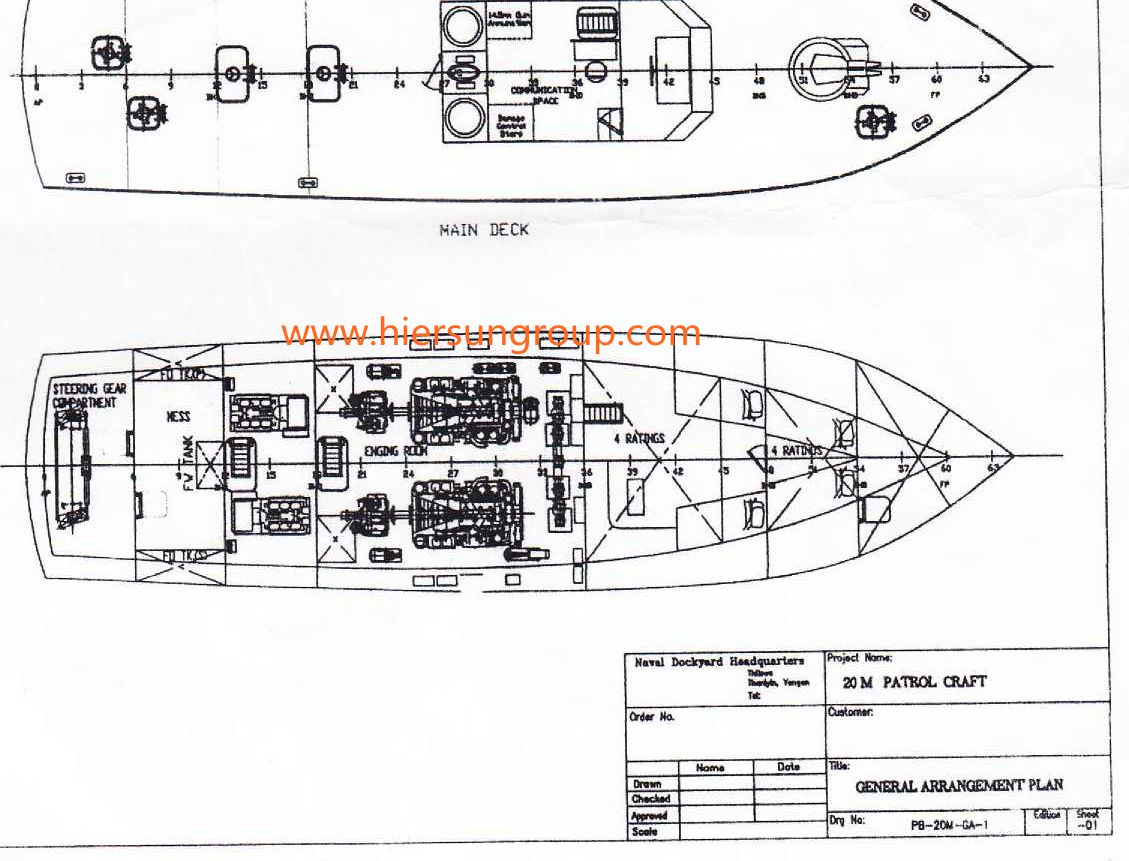

. intercooled, indirect cooling, V configuration diesel engine of continuous output power about 900 RHP MCR at 42 ℃ Ambient temperature, 90% humidity and at 25 deg C seawater temperature. The speed of the vessel at standard displacement i.e 45 tons (approx.) shall be not less than 22 knots. If NECESSARY to approve the speed, the supplier shall carry out towing tank test, Required Engine Power estimation can be checked by the supplier on the basis of the proposed hull form and General Arrangement plan. If necessary, alteration of lines might be advised

(2) Starting System

Electric Starting system consisting of:

(aa) Gear rim flywheel, _

bb Engine mounted starting motor, 24V. 2 poles.

Cc Engine mounted Dynamo for charging batteries.

Dd Wiring for starter motor and dynamo.

Ee 24V DC Lead acid batteries complete with starting cables.

(3) Cooling system

All necessary pipes, pipe fittings. Expansion (Flexible Joint) and valves for engine system (Engine cooling. Fuel, etc.) shall he supplied by the tenderer.

Monitoring and control system

All necessary Ship Wiring Control cables are supplied by the tenderer.

Safety shutdown by Solenoid

Actuated at low lub oil pressure

Overspeed.

Crankcase overpressure

Output Shaft arrangement

flywheel

flexible coupling.

Piping: and Valves

Mounting of main engine and gear box

The- main engines and gear boxes will be supplied with mounting feet which are suitable for mounting on the girders (seating) by the chock fasting method. The chock fasting of engines and gears will he carried out by the engine supplier as part of the commissioning of the propulsion system. Chock fast shall be supplied by tenderer in appropriate time trams before shafting alignment. Initial filling of required oils for engines and gearboxes must also be supplied by the tenderer.

For each engine, instrument panel for wheelhouse as specified and maker's standard:

aa) Engine tachometer,

bb) Shaft tachometer..

cc) lub oil pressure gauge

dd) 2X exhaust gas temperature gauge after turbocharger

ee) cooling water temperature gague.

ff) lub oil temperature gauge

gg) start-stop push botton

hh) engine speed control and clutch control

ii) Group alarm panel

Alarm panel for installation in wheel house for the following:

aa) Main engine

bb) low level alarm of fuel daily tanks

4) Engine telegraph

For wheel house, indicator lamp type for (ahead, standby, dead slow, slow, half, full indication, with call bell and failure indicator, 24V, DC system, complete with spare bulbs,

D) Stern arrangement

Complete stern arrangement with careful material and strength, selection compactible fot Aluminum hull, consisting of Hydraulic marine reverse reduction gearbox, shaft struts., Coupling 'flanges & bolts, Propeller nuts, fixed pitch propeller, cap nuts, Stuffing boxes complete with gland, water lubricated Cutlass bearing, Shaft bracket boss, etc.

No | Description | Set |

| 1)Steering system (Electro-hydraulic power steering) complete with fall follow up. non-ibllow up system end emergency system, electro-hydraulic double acting ram type complete with relief valves, by-pass valves, base plate, cocks and fittings. Design parameters are as follow: Design speed: 22 knots No of rudders: 2 Nos Effective torque on two rudders: 2x2.8 kNm Maximum rudder angle: 85 d.eg. Steering system must be complete with the following: Hydraulic power pack Simple to install:, reliable and with motor and pump located on the top. easily accessible for maintenance. 2) IP 44 electric motors,-variable volume pressure compensated piston pumps, return line filter, solenoid operated directional control valves, pressure relief vaivefadjustable}, low pressure alarm switch, lifting eyes and drain plug, (Tested for specified Sow, Pressure arid function) (3) Synchronizing rods as appropriate per Manufacture's design (4) Steering Control System (Wheeihouse) Complete with follow up aa) control level bb) ( Non follow up joystick Steering rudder angle indication (with dimmer} cc)Station selector switch ee)Mode section switch (ff) Control panel of hydraulic power pack gg) One set of emergency manual hydraulic steering system including Iieim -pump, safety bypass valve, steering wneei (3G0mm) diameter of stainless steel or appropriate. (5) Pipe arid Pipe fittings (Stainless Steel) (aa.) Pipes . (bb) Pipes joints (straight upon fittings) (cc) Elbows (dd) Valves (ff)fittings (ggj Pipe clamps with fastening bolts (hh) Sfarter panels, providing all. the necessary brakers and saiety devices and as well as the transfer of tile control from the steering compartment to the bridge and open bridge. (6) Rudder stock. Trucking and bearings must be carefully designed based on strength ead material selection for aluminium hull. (7) One set of standard spare parts as recommended by classification societies, for 3-5 year services. fg) 3 sets of Instruction Manual in English. (9) Type approval certificate from ABB or equivalent, (10) Technical information for power supply is . aa) 4I5V, AO, 50 Hz , 3 phase (bb) 220V. AC, 50 Hz , 2 phase (cc) . 24V) DC (11) Original equipment manufacturer (OEM) is Kobelt (Canada) or Equivalent, (12) For reference to estimate the length cf pipes and quantity of pipe fittings, the following lengths between each station are provided: Wheel house and steering gear compartment: 16 m. n p,o information, pamphlets and drawings should foe incGrpora.tzd with the Weight of each unit should be mentioned in uie quotation. |

|

| (F) Engine Room Ventilation. Axial Flow Blowers (1) Electrically driven, 415V. AC, 3 phase, marine type, necessary accessories so that each unit is complete for ready installation, supply airfoil fan for engine room with starter switch, capacity is I approximately 7500 cfm at 1.5 inches water at static pressure. |

|

| electrically driven, 220-V. AC, 2 phase or 415V, AC, 3 phase, marine type, necessary accessories so that each unit is complete for ready installation, supply airfoil fan for generator room With starter switch, capacity is approximately 706 cfm at 1 inches water at static pressure, |

|

| (G) Tools and Spares full Sets sets of special tools aa gineaa) engines and turbocharger. (bb) gearbox and propeller. Cc) basic tool kits with torque-meter (chain blocks, boxxspanners, etc) cc) Basic tool kits with torque-meter (Chain blocks, box |

|

| Main engine (a.a.) Spare filters for L.O and F.O for 5,000 Hours of operation. (bb) Spare parts for main engines for 5,000 hours of operation, (cc) Recommend Spare parts for main engines for 10,000 hours of operation. (dd) One set of crankshaft bearing ring for repair. |

|

| propulsion system (aa) Spare propeller (Left & Fight) (bb) Stem tube bearings, propeller shaft bracket bearing (Left & Right), |

|

| Notes: 1) All equipment and components quoted are to be of reliable and reputable, make and supplier is to state maker, type or model number for each item. 2) The supplier is to provide one year warranty of ail machinery and electrical equipment while in storage and a further one year performance warranty from date of commissioning 3) Quotations must contain complete detailed technical specification accompanied by manufacturer's illustrated brochures, catalogues and drawings. 4) Detailed Itemised inventory lists are to be provided for each sub¬group of spares and tools mentioned and prices for each sub-group are to be stated. 5) Preference shall be given to supplier which can quote all items as a package deal. 6) Consideration shall be given to suppliers which can quote competitively forquality products for a certain lot of items which can be considered independently from the rest of the whole lot of items. |

|

If you have similar project undergoing Please contact us for a proposal.